EMC & Microwave Absorbers

What is an electromagnetic absorber?

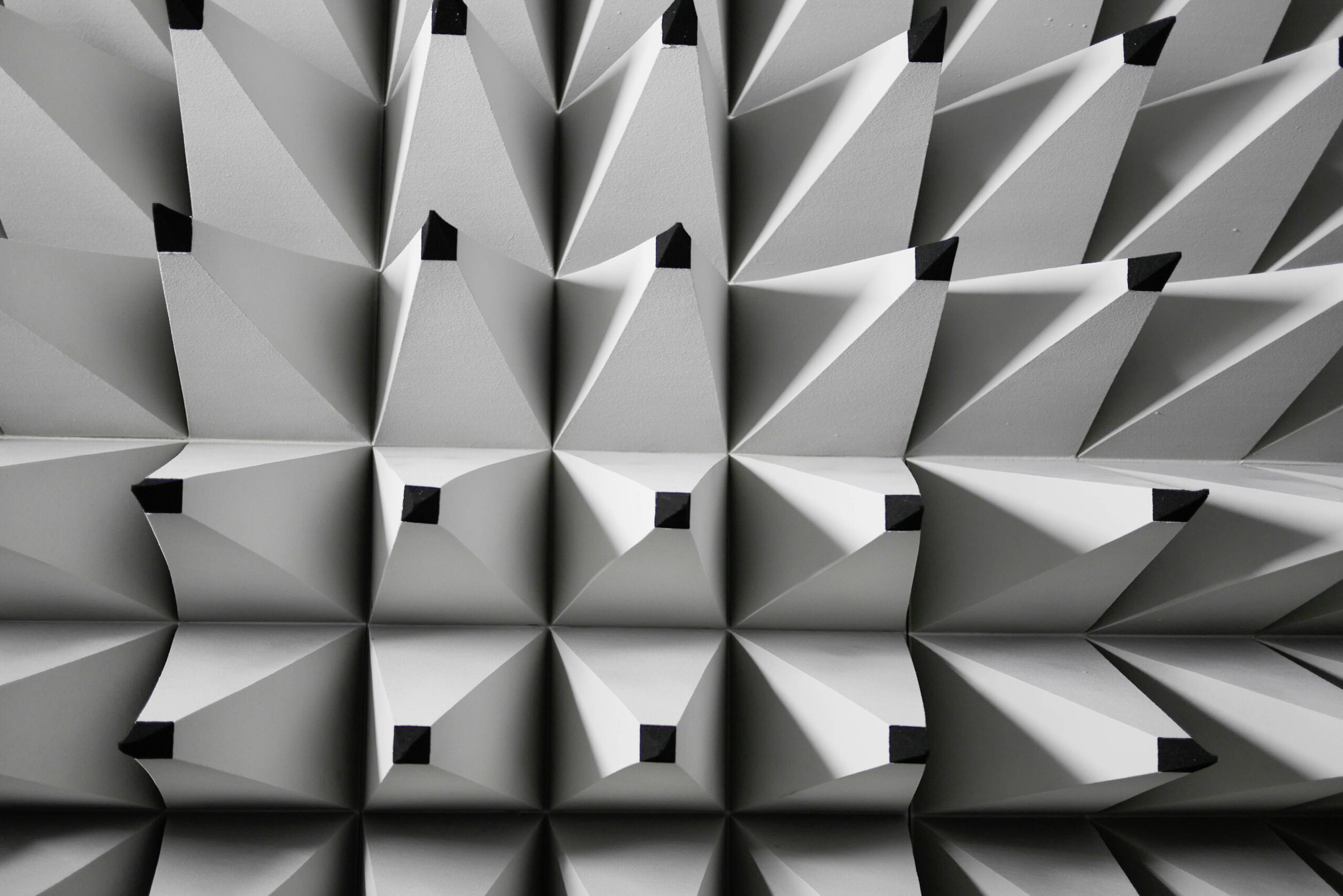

Absorbers are necessary in order to reduce or eliminate the reflection of electromagnetic waves. They can be placed within an enclosure that is impermeable to waves or used as standalone solutions.

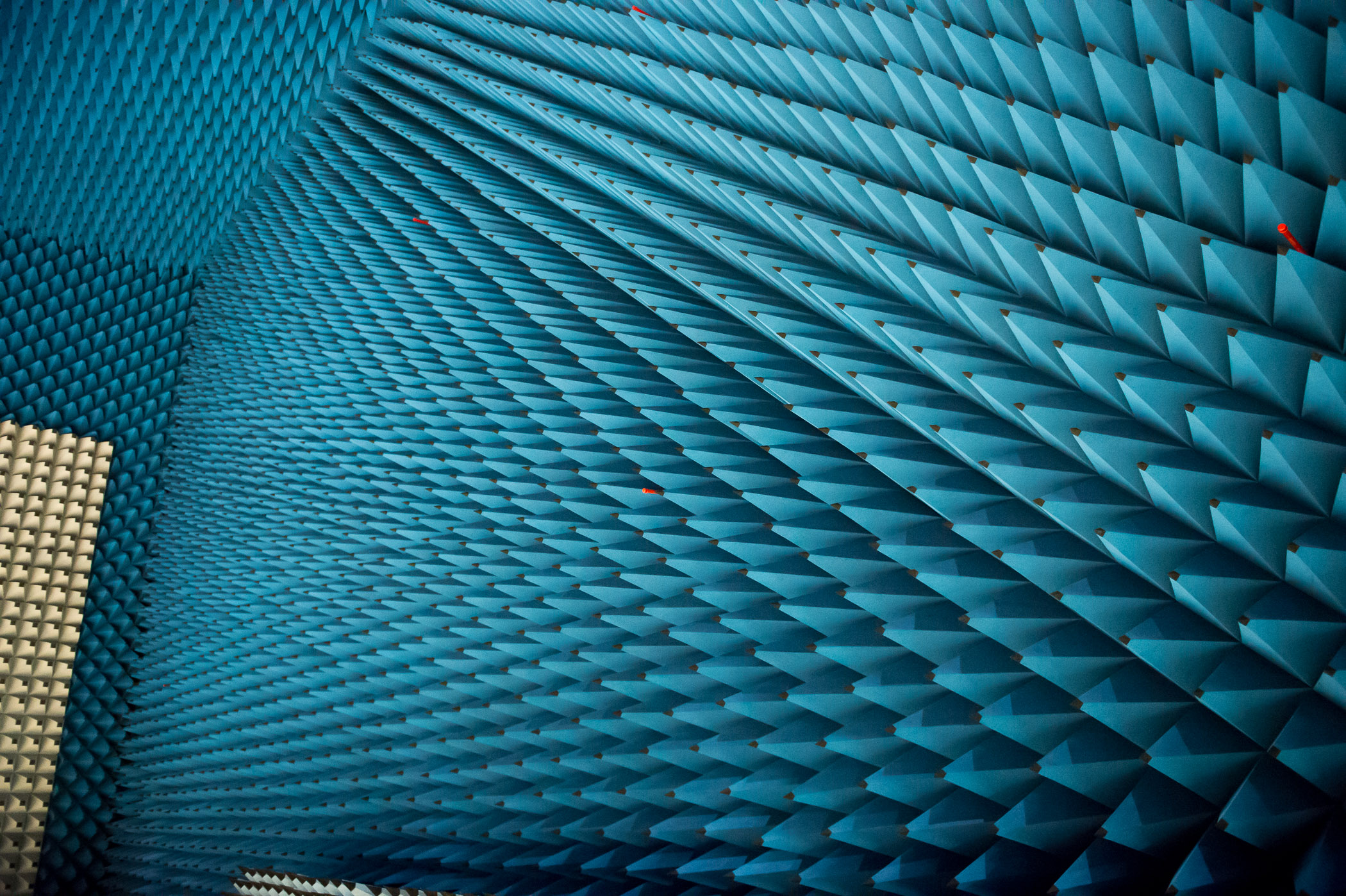

When integrated in shielded rooms, they form an anechoic chamber which makes it possible to provide:

- Precise, repeatable test conditions for EMC (Electromagnetic Compatibility) and antenna measurements (RF/hyperfrequency).

- An environment similar to that of free-space.

The dimensioning of the shielded structure and the arrangement of the selected absorbers guarantee the performance in the defined test area within a frequency range going from a few MHz to several tens of GHz.

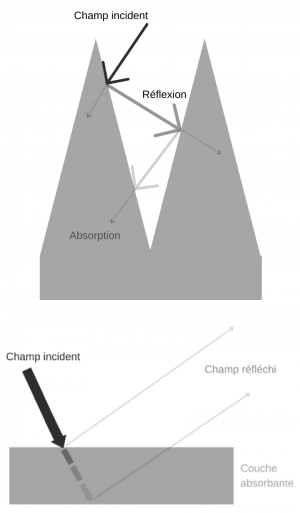

The height of the absorbers (which is a function of the wavelength) depends on the required low frequency together with the desired level of reflectivity. The waves are gradually absorbed or reflected as they penetrate.

The performance of an absorber is defined in terms of the reflected and not the absorbed energy. This parameter is known as reflectivity and is measured in dB. A reflectivity of -10 dB indicates a 90% reduction of incident electromagnetic waves and a reflectivity of -20 dB, indicates a 99% reduction.

The performance of an absorber is defined in terms of the reflected and not the absorbed energy. This parameter is known as reflectivity and is measured in dB. A reflectivity of -10 dB indicates a 90% reduction of incident electromagnetic waves and a reflectivity of -20 dB, indicates a 99% reduction.

The reflectivity performance is checkedin factory and/or following installation of the anechoic chamber on the basis of applicable standards or a specific test plan.

Power handling is another criterion to be taken into account in the light of the intended application (compact base station, antenna measurements, etc.).

Classification of absorbers depending on frequency range

There are two main categories of absorbers:

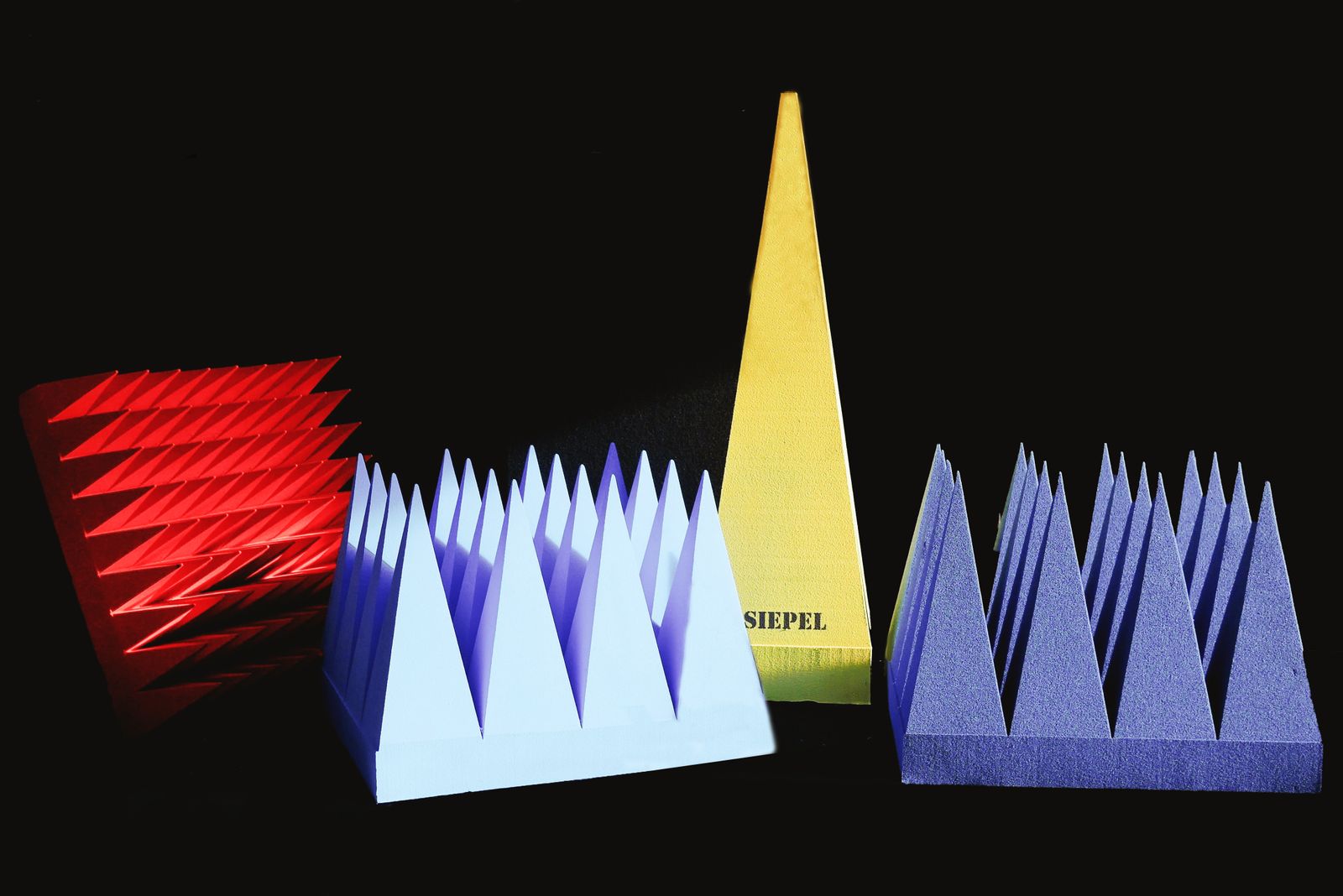

- Narrowband absorbers: flat resonant absorbers of limited thickness (from 1 mm to 4.3 mm). These function within a narrow frequency band (1.5 GHz to 24 GHz);

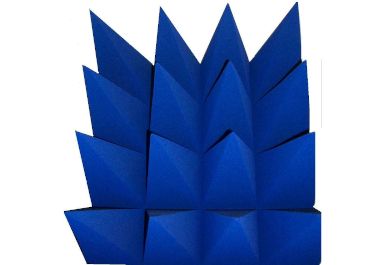

- Broadband absorbers: made from pyramidally shaped material that covers an extended wave range (from a few tens of MHz to 40/110 GHz). Their thickness can vary from a few centimetres to over two metres.

Characteristics of Siepel absorbers

Manufactured by Siepel in France, these absorbers are the result of research focusing on the optimization of the equipment geometry and composition.

They comply with the following characteristics and standards:

- Reflectivity performance: contractual guarantee

- Technology: polyurethane foam impregnated with carbon

- Power handling: from 2 kW/m² to 15 kW/m²

- Temperature resistance: from – 65°C to +200°C

- Compliance with fire resistance standards and recommendations: ISO 11925-2 Euroclass E, NRL 8093 – tests 1, 2 & 3, DIN 4102 – B2

- Use in clean rooms: ISO class 4 in accordance with ISO 14644-1

- Respect for environmental standards: raw materials compliant with the REACH & RoHS Directives

- Ageing: excellent service life (> 25 years)

- Made in France: control of the production line and available stock

LIV coating: a unique coating

Moreover, we have developed a coating specially designed for our absorbers: the LIV coating, which provides both flexibility and strength. It provides the freedom necessary to customize chambers thanks to the large choice of colours and levels of brightness. Furthermore, the LIV coating represents an alternative to the white caps which impair performance at high frequencies.

Factory and on-site quality controls

All manufactured products are subjected to systematic monitoring as set out in the procedures defined by our quality management system, which is based on ISO 9001. Siepel performs factory acceptance tests (FAT) and/or site acceptance tests (SAT) following installation.

Siepel, a well-established market force

Choosing Siepel is to choose a company which:

- innovates through the market launch of very wideband multilayered absorbers painted with a plasticized LIV coating, high-power absorbers, the design of EMC chambers with partial coverage, etc.;

- meets the demanding constraints of exacting applications such as aeronautics and aerospace;

- supports you during project definition and the installation layout for the required absorbers;

- guarantees reflectivity performances up to 110 GHz.

Siepel possesses a list of important reference customers in France and internationally, embodying different levels of complexity, sizes and types of application (industry, telecommunications, RCS radar, compact base stations along with defence, aeronautics and aerospace applications).

Siepel will assist you when choosing your absorbers, whether purchased separately or integrated in a shielded cabinet or anechoic chamber. In this latter case, we have the expertise necessary to offer you a chamber design that is appropriate for your test object and the host building, to manufacture the entire chamber and to guarantee every aspect of its performance. Our absorbers can also be used for the renovation or upgrading of your existing installation.